Since the late 1800's split cane fly rods dominated the fly fishing market for decades until the introduction of synthetic fly lines. Before this braided silk fly lines were the only choice for the fly fisher during the first half of the twentieth century, however these lines were expensive to produce and were considered high maintenance.

The first synthetic fly lines were introduced in the period following World War 2, when the Cortland Line Company introduced their 333 fly line. This was the first fly line where a polyvinyl chloride (PVC) coating was applied to a core of braided Nylon, Dacron or Fibreglass. The slickness and buoyancy of the line being determined by the PVC sheath and the inside core determining its strength and flexibility. Combined the sheath and core determine the lines overall diameter and weight. In the case of floating lines the purpose of this manufacturing method was to trap microscopic bubbles within the PVC sheath allowing the lines to float, much the same as a greased silk fly line would. The major benefits of this new manufacturing technique were that the lines were cheaper and easier to control in mass production and required less care in the field.

With the arrival of the new lines a new system of line designation was introduced, meaning the older braided line systems which were based on line diameter were replaced with a modern system based on line weight. The new system developed by the American Fishing Tackle manufacturers Association (AFTMA) required that the first 30 feet of a synthetic line be the same weight as the old silk line designated equivalent. Since natural silk is denser or heavier than the synthetic materials used in modern lines it meant that synthetic lines needed to have a wider diameter, or more bulk, to match equivalent fly rod ratings. The new manufacturing process not only allowed for cheaper production, but what is more important, the added control in production meant that by varying the diameter of the PVC sheath manufacturers could create new weight forward and shooting tapers. Now the modern fly fisher could target new species in new environments which were traditionally not possible this was especially evident in the growth in popularity of saltwater fly fishing.

Modern fly rod manufacturers have kept abreast of these changes by focusing their attention on high-modulus, fast-action carbon rods which now dominate the market. Carbon as a material has allowed for longer, stiffer and lighter rods which allow us to throw longer casts and generate the lines speeds to overcome the added drag of the line and larger or heavier flies. Carbon rods, much like synthetic fly lines, are cheaper and easier to control in mass production and require less care in the field. Today many fly fishers believe that bamboo rods are heavy, fragile and that they have slow actions. However, especially in the traditional realm, this is simply not true. For the purposes of this discussion I would like to focus on this traditional realm of fly fishing namely streams, rivers and small still waters.

The main advantage amongst users of carbon rods, is their weight. It is true, given the hollow structure of carbon rods, any comparable 9 foot rod of more than a 6 weight will be considerably lighter than an equivalent bamboo rod. However, up to 9-foot and less than 6 weight this difference in weight is far less noticeable. A 7'6 5 weight split cane fly rod and a modern 8'6 5 weight carbon rod I measured recently differed by only 10 g.

Split cane fly rods are also remarkably resilient. A modern heat treated and impregnated blank is remarkably resistant to sets and water damage. There have been instances of such cane rods being left in rivers for months at a time before being reclaimed. Once cleaned these rod blanks were as good as new apart from the handles and components which needed to be replaced. Impregnated blanks have another advantage, that when nicked or scratched one can simply buff them with a smooth cloth to raise the varnish and restore the finish. This nick or scratch could mean the end to a carbon rod blank and usually at an unexpected moment.

Let us now consider the solid structure of split cane fly rods. This is an important quality to consider and which is also one of its advantages. The solid nature of bamboo rods gives them greater mass and, as we discussed above, therefore weight than carbon rods, this additional weight makes them very smooth casting throughout the stroke. In addition when a split cane rod flexes its core fibers become compressed, thus making the rod stronger and giving them a unique loading characteristic or feel, this is particularly evident when roll casting. Carbon rods tend to adopt an oval (weaker) shape under extreme pressure as they lack this internal support. These qualities of bamboo fly fishing rods mean that you do not need fast line speeds to present a fly a given distance. Take the time to become accustomed to their slow and fluid actions, and let the rod do more of the work.

It is important to note that historically split cane rod actions were designed to cast braided silk lines in the traditional realm of streams, rivers and small still waters. It is here that these lines have two noticeable advantages over modern synthetic fly lines. First, braided silk fly lines are on average 30% thinner than equivalent modern synthetic fly lines, this 30% reduction in diameter equates to the equivalent of a 69% reduction in surface area and drag, meaning that less effort is required to cast the line a given distance and that they are less affected by windy conditions. Second, braided silk lines being less bulky are also denser than their synthetic brethren and provided that they fall in the same AFTMA class will land more delicately and with less splash than an 'equivalent' synthetic line. These properties combined with the fact that they have little stretch and no memory, give braided silk fly lines unparalleled feel and control, ideally suited to slower actions, and a relaxed cast.

Bamboo is a natural material and remains unchanged. However many new bamboo rod tapers have been developed since the introduction of synthetic lines, and many faster, tippier actions are now available. These actions have been specifically designed to ease the transition from carbon fly rods. At the same time many synthetic fly line manufacturers have developed coatings and tapers which are more suited to these bamboo rod actions. The result is that many fly fishers can now benefit from the best of both worlds, whether they would like a traditional full action bamboo rod which bends all the way to the butt and delivers the fly slowly, or a faster more progressive action.

There is also the natural aesthetic beauty of a bamboo fly rod, the honey colour of the blank, the fine thread wrappings and their beautiful components. The weight, feel and smell of them, the knowledge that someone spent years learning the crafts needed to make this, and then spent weeks making the rod in your hand gives them a substance and character that synthetic rods will never simulate. There is also a subjective benefit I believe bamboo rods offer which is too often overlooked, and that lies in their care. The ritual of wiping down, drying and storing the rod seems justified for something that is built to be passed down from generation to generation. Anyone lucky enough to be passed down a bamboo rod from parent or grandparent should consider the care taken in preserving this rod to this day and the many enjoyable days it has spent in hand on the water.

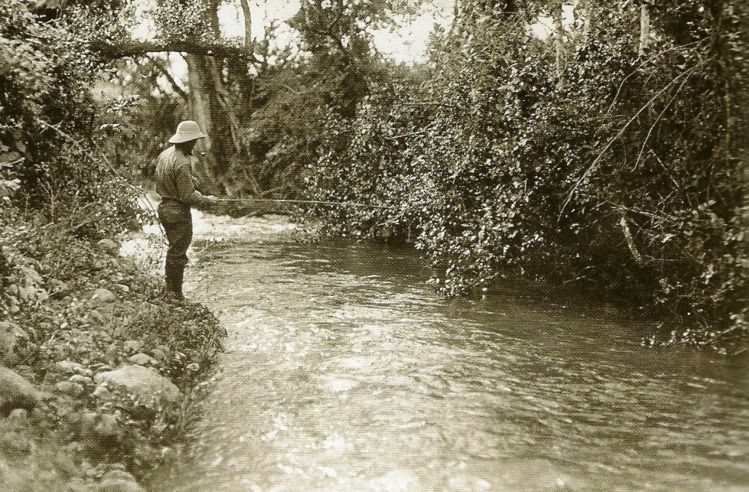

Therefore, why choose a split cane fly rod? The answer simply is that when fly fishing in the traditional realm of streams, rivers and small still waters, where modern actions are not a requirement, they allow for improved casting efficiency, a more delicate presentation and a feel not possible with modern synthetic fly rods. Often viewed as an expensive luxury for the purist, bamboo rods have substance and a character that will serve to enhance your overall fly fishing experience.

Read our article on How a split cane fly rod is made